Connectivity failures in a manufacturing environment rarely announce themselves with a bang. Instead, they creep in quietly. For instance, a slow-loading interface or a delayed machine signal. By themselves, these instances might seem trivial. Together, they chip away at the synchronized flow of modern production.

CONTENTS

Latency Is the Enemy of Precision

On paper, the line moves. Machinery pivots, conveyor belts cycle, robots weld. In practice, every action depends on milliseconds. A split-second delay in data transmission can result in production irregularities. Errors multiply, invisible until inspection flags them downstream. However, this is not hypothetical. This is a reality for factories with weak networks.

Poor internal infrastructure forces workarounds like manual data entry and repeat scans. These are signs of digital fatigue. Production teams work harder to compensate, but the system never speeds up. It stays bottlenecked by the very network intended to support it.

Operational Costs Multiply Quietly

Weak network connections cost more than they appear to. Scheduled downtime becomes unpredictable. IT teams spend hours patching routers, switching access points, tweaking bandwidth. Engineers sidestep digital controls, relying on paper-based methods. Errors increase. So does labor. Overtime budgets grow. Quality dips slightly. Rework spikes.

All of this costs money. Not just in labor or materials, but in missed deadlines, late shipments, and customer churn. A single late order might result in a contract review. Several can end a relationship altogether. The perception of unreliability grows faster than teams can counter it.

Security Risks Follow Poor Connectivity

Weak networks do more than slow things down. They open doors. Devices that cannot update become vulnerable. These lags in network monitoring tools leave gaps in visibility. Threat actors are not always looking for flashy exploits. Sometimes, it’s the unmonitored corner workstation running outdated firmware that gives them access.

Factories often have a mix of legacy equipment and new digital tools. This combination becomes risky without a stable network. A vulnerability in one area can ripple across the network. Isolation is difficult when data pipelines are patchy or inconsistent. Monitoring every device becomes impossible if network health cannot support it.

The Human Impact Is Real

They are people operating alongside these rows of machines. People that can very well be affected by a weak or struggling network. Operators have to delay tasks while their screens buffer. Maintenance staff struggle to access diagnostics. Management faces decision paralysis when data reporting lags behind.

Training can even be affected. As more processes move digital, staff need reliable access to e-learning, digital manuals, and real-time guidance. If the network fails, the training effort fails with it. Employees lose trust in the tools they are supposed to rely on. That loss of confidence erodes productivity.

Modern Solutions for Modern Strain

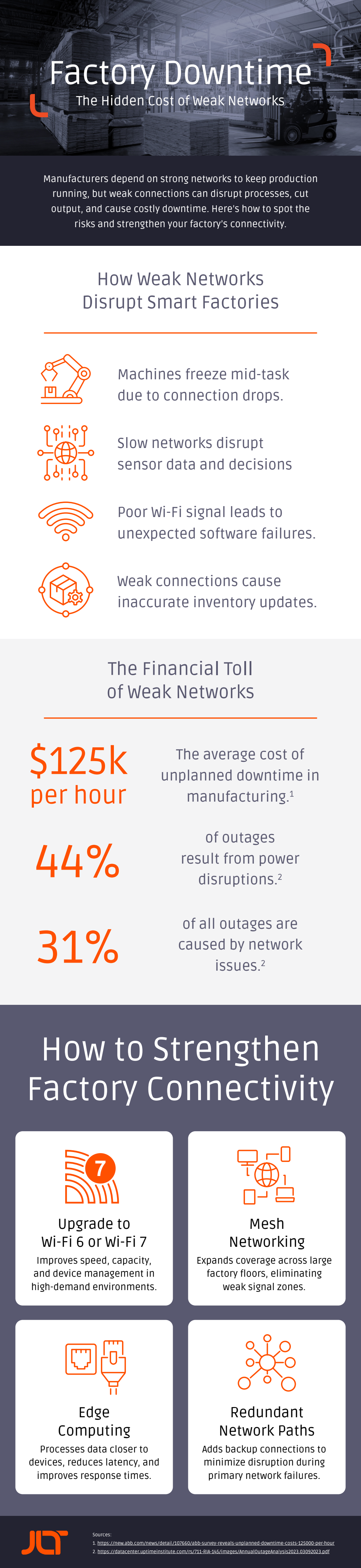

A healthy infrastructure is not a luxury, but a foundational requirement nowadays. Despite wired solutions still dominating many factory operations, wireless technology has proven to be invaluable. Take for instance, edge computing, 5G integration, and mesh networks. These advances distribute load more evenly, reduce single points of failure, and allow critical systems to communicate even when disrupted.

Hardware matters as well. Durable, factory-ready tools support these networks. An industrial tablet, for example, provides staff with mobile control and diagnostics without sacrificing reliability. These are not consumer-grade devices. They are built for production floors, with connectivity in mind and durability at their core.

Future-Readiness Starts with Connectivity

Manufacturers who invest in automation, data analytics, and machine learning cannot successfully implement these tools without a stable network. They are foundational for an efficient and productive factory. Every production goal relies on timely, accurate, and uninterrupted data.

Upgrading network infrastructure may not carry the allure of a new machine or flashy innovation. But it is the prerequisite for every efficiency gain that follows. The cost of delay, error, and inconsistency will always exceed the investment needed to strengthen the digital foundation.

Factories cannot afford to treat connectivity as an afterthought. It is the quiet system behind every process, and when it fails, so does everything else. For more information, check out the accompanying infographic.

Hey, I’m Jeremy Clifford. I hold a bachelor’s degree in information systems, and I’m a certified network specialist. I worked for several internet providers in LA, San Francisco, Sacramento, and Seattle over the past 21 years.

I worked as a customer service operator, field technician, network engineer, and network specialist. During my career in networking, I’ve come across numerous modems, gateways, routers, and other networking hardware. I’ve installed network equipment, fixed it, designed and administrated networks, etc.

Networking is my passion, and I’m eager to share everything I know with you. On this website, you can read my modem and router reviews, as well as various how-to guides designed to help you solve your network problems. I want to liberate you from the fear that most users feel when they have to deal with modem and router settings.

My favorite free-time activities are gaming, movie-watching, and cooking. I also enjoy fishing, although I’m not good at it. What I’m good at is annoying David when we are fishing together. Apparently, you’re not supposed to talk or laugh while fishing – it scares the fishes.